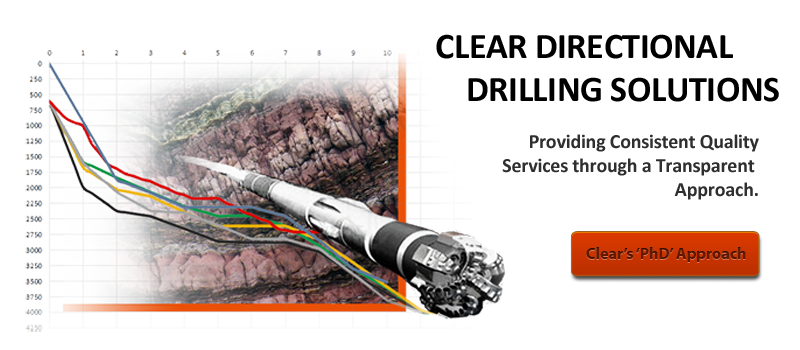

Clear Directional's "PhD" Approach

clear (klir) adj. 1. transparent 2. distinct 3. keen or logical

Clear is a corporation which provides consistent quality directional drilling services to the energy industry.

Its' comprised of a team of industry recognized professionals, using a "PhD" approach - Passion - about what they do, Hard work - striving to meet clients needs, and Determination - in providing a consistent quality of service time after time.

Clear Directional is an oilfield services corporation, focused on providing directional drilling solutions to the energy industry.

Its' comprised of a team of industry recognized professionals, using a "PhD" approach - Passion - about what they do, Hard Work - striving to meet clients needs, and Determination - in providing a consistent quality of service time after time.

Our dedicated team is focused on service quality from all aspects of the directional process.

We work closely with our clients to understand their objectives, from the geological play, production utilization, and wellbore placement, to final total depth of well.

Passion - Hard Work - Determination

- Horizontal

- Directional

- Slant

- Re-Entry

- Vertical Wellbore Monitoring

Operational Services

Clears operational excellence spans a multitude of directional facets. We have performed horizontal well services, with "tight" geological window target tolerances, to consistently landing build sections in a single run.

Keeping tangent sections constant to allow for more rotation, thereby reducing time of directional wells, optimizing slant wellbore placements for minimal ground disturbance impact, executing re-entry wells, by carefully time drilling to exit in a manner of low dogleg making for ease of well completions to wellbore monitoring operating cost effectively, by minimizing directional control and thereby effectively speeding up the drilling process.

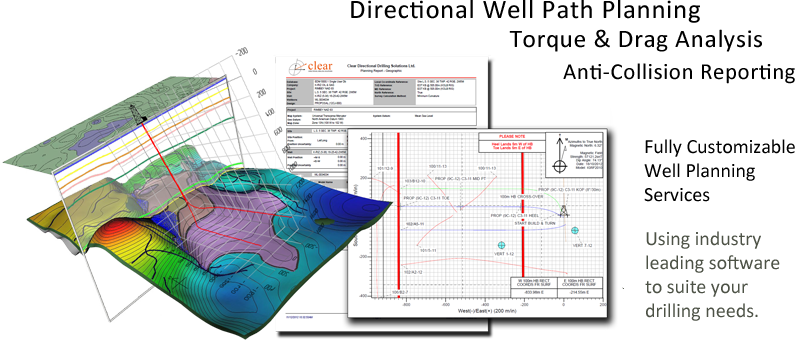

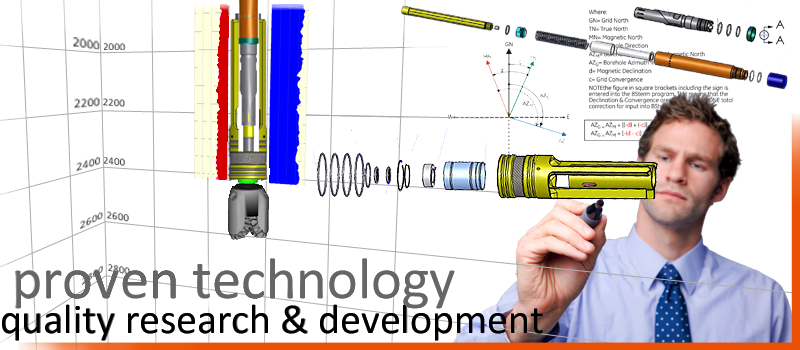

Technical Services

Clear's technical and well design team have been engaged to architect some of the most challenging and demanding directional and horizontal wells. The expertise utilized is a culmination of initial client interface coupled with practical design configurations to be able to operationally execute and deliver these wellbore placements.

Software tools, with ingenuity and operational input consistently satisfy geological parameters, ultimately aiding in effective wellbores to yield productive hydrocarbon reservoirs.

Time sensitivity and attention to detail are hallmarks that our clients have appreciated and grown accustomed to.

- Drilling Insurance

- PDM Rentals

- Jars

Additional Services

Clear offers additional services to the energy industry to aid in the pursuit of hydrocarbons. Positive displacement motors (PDM's) are available to rent for performance drilling or "clean outs" of existing wells. Drilling jars to reduce the instances of being stuck while drilling as well down hole equipment insurance can be purchased in advance of directionally drilling to minimize the risk to energy and production companies.

In addition, Clear has been proactive and is constantly exceeding the needs of its clients through research and development initiatives. We have incorporated short bit to build drilling motors to achieve desired build rates, designed MWD components to minimize impacts in hostile environments or from artificial vibration equipment, configured parts for larger wellbores, designed a filtering/amplitude system to enhance signal : noise ratio allowing for greater effectiveness of surveying with Electromagnetic telemetry, and composed a degaussing program for the potential impact of magnetic anomalies.

Safety

Clear conducts "Tailgate" safety meetings as part of its corporate guidelines and has Fatigue Management Policies in place amongst others. Further to this, Clear requires all of its field representatives to review its Safety Policies. We are IRP-16 compliant with ENFORM, have received our SECOR and are compliant with ComplyWorks and ISNetworld.

Directional Drilling

Directional, Horizontal, Slant drilling... More...

FAQ | Directional Drilling

What are typical build rates for horizontal wells?

The Build Up Rates (BUR) for horizontal wells will vary pending on the geological formations encountered while drilling combined with, motor and bit selection, and hole size but generally build rates of 6°/30m to 8°/30m are common.

What is the maximum motor setting that is rotable?

Rotating of Positive Displacement Motors (PDM's) vary with manufacturers and their guidelines. A general rule is to not rotate a setting greater than 1.83° as a risk of failure may occur. Much of this is premised on drilling parameters such as amount of rotation, hole size, weight on bit and the formation.

What kind of doglegs will the tools safely pass through?

Measurement While Drilling (MWD) tools will pass through the doglegs they drill through. The sensor package within the tool is stabilized to withstand rotational and bending stresses within certain tolerances. The tools can move through a 20°/30m dogleg sliding, as rotating through this could cause a malfunction of the components due to the stresses.

What is the minimum angle that is effective when drilling a directional well?

To optimize drilling a directional well, where more time is spent rotating vs. sliding the drill string some basic guidelines can be followed:

- A terminal angle of greater than 12° allows to still utilize gravitational forces (less sliding to maintain angle to target)

-angles less than 30° still allow for conventional wireline logging tools to be used

How important are survey's from nearby existing wells?

When planning wells where existing or nearby wells exist, knowing the distance relative to the proposed well is imperative. Surveys from these wells if available aid in collision avoidance through software creating anti-collision models. Without surveys, a "worst-case scenario" can be generated by theoretically deviating the existing wells towards the proposed well path.

Measurement While Drilling

EM, Positive Pulse, Gamma Ray... More...

FAQ | Measurement While Drilling

How often are MWD and Gamma Ray tools calibrated?

MWD and Logging While Drilling (LWD) i.e. Gamma Ray equipment are checked and calibrated prior to their assignments. They must fall within specifications set out by manufacturers in order for them to function and work properly. Additional checks are done in the field, prior to running in the hole (roll check) and while running in the hole (shallow check) to assure correct working order and communication with all probes within the string.

What distance are the sensors from the bit?

Sensor distances vary for MWD equipment, as the makeup of the Bottom Hole Assembly (BHA), motors, Non-Magnetic Drill Collars (NMDC), Gamma Ray etc. will somewhat affect placement. Conventional directional equipment distances are in the 11-13m range from the bit, and a finalized distance is given with the known BHA.

Do solar storms or solar flares affect surveys?

Magnetometers that make up part of the sensor package in the MWD tool measures direction (azimuth) downhole. Solar activity along with latitude (Earth's poles) will have a pronounced affect on tool readings. Survey quality needs to be more closely monitored during these instances as when Solar storms originate from the sun's surface they are deflected by the earth's gravitational field producing a geomagnetic storm affecting magnetic declination readings, sometimes as high as 7°. Through the use of magnetic monitoring data sites, this can aid in reducing the affect on survey quality.

General Questions

Land Surveys, Planning Requirements... More...

FAQ | General Questions

What is a datum?

A geodetic datum consists of a reference ellipsoid that is anchored to a certain area of the Earth to

best represent that area's surface. This defines the shape and size of the earth and the origin/orientation of

the coordinate system used to map the earth.

Is there a difference between NAD27 and NAD83?

Yes, with varying differences depending on the location in question. North American Datum of 1927

(NAD27) is based on the Clarke 1866 ellipsoid that originates at Meades Ranch, Kansas, USA (with the geoidal height

assumed zero).

North American Datum of 1983 (NAD83) is based on the GRS80 ellipsoid, with a 'geocentric'

origin, best used for North & Central America.

What is the requirement for surveying in the wellbore?

It is good practice to take survey measurements (inclination and azimuth) every 30m (1 single) to identify where you are located in the wellbore. This at times is increased (nearing a landing point, waypoint or existing well) or decreased (drilling vertically to Kick Off Point-KOP). Government regulations will stipulate the frequency of this as well i.e. Alberta-every 150m.

What is the difference between Build Up Rate (BUR) and Dog Leg Severity (DLS)?

BUR takes into account the amount of angle over a prescribed length (30m or 100') between two survey points to achieve a certain angle while Dog Leg Severity (DLS) also takes into account the change in direction (turn) over the same course length. These may impede drilling operations such as tripping or running casing should a wiper trip not be done.

Our Work

Our WorkThroughout Western Canada and the Northwest United States of America Clear has successfully drilled numerous horizontal and directional wells. Please click on the province/state of interest to see what drilling fields/target formations Clear Directional excels in.

Areas of special note where a significant number of wells have been drilled are Swan Hills, Beaverhill Lake formation, Waskada, Amaranth/Spearfish formation, Cochrane, Cardium formation, Olds/Garrington, Viking and Ellerslie formation, Kaybob, Dunvegan formation, Evi/Otter, Slave Point formation, South East Saskatchewan, and Provost.

More...

More...

This section has been designed as an informative forum to access everyday useful information on equipment, well planning, land survey systems, conversion tables, guidelines and various online field calculators. Along with the various reference material, you can also find information on our Area Statistics and Drilling Curves highlighting the work we have performed through out North America.

Use the toolbox menu on the right to navigate through to your topic of choice.

Area Statistics

Clear Directional has extensive history and knowledge of numerous drilling locations in Western Canada and the United States of America. Shown below is a sample of our areas of experience.

Operations Facility | Stony Plain, Alberta - Driving Directions

Clear Directional is looking for talented, driven individuals to join their team.

Apply Now