Below are various tools that are useful in regards to directional drilling:

Sidetracking Guidelines

Sidetracking GuidelinesThe following guidelines are used to aid in understanding and in establishing some protocol in the event of having to sidetrack while drilling. Although this may not cover all circumstances, it gives useful information for both the desk and field engineer.

Stage 1 |

3-4 min/inch - First 2-3m |

Visually 20-30% Formation observed in cuttings |

Stage 2 |

2-3 min/inch - Next 2-3m |

Visually 50% or > observed in cuttings |

Stage 3 |

1-2 min/inch - Last 3m or more |

Visually 80% or > observed in cuttings, reactive toque apparent and bit taking on weight |

Stage 1 |

3-4 min/inch - First 2-3m |

Exercise caution and patience using light weight |

Stage 2 |

2-3 min/inch - Next 2-3m |

Observe any reactive torque and bit taking on weight |

Stage 3 |

1-2 min/inch - Last 3m or more |

Continue to control drill further to 5,000-8,000daN WOB |

Stage 1 |

5 min/inch - First 1m |

Exercise caution and patience, survey every 0.5m |

Stage 2 |

4 min/inch - Next 2-3m |

Survey every meter determine if Whipstock has moved from original orientation |

Stage 3 |

2.5 min/inch - Next 4-5m |

Survey every meter as required |

Stage 4 |

1.5 min/inch - Next 2m |

Continue to survey every meter |

Stage 5 |

1 min/inch - Till 20m away |

Survey to determine if MWD providing good inclination surveys and 20m away bottom of Whipstock |

Dominion Land Survey Guide

Dominion Land Survey GuideTOWNSHIP, RANGE, & MERIDIANS The main objective of the Dominion Land Survey is to identify parcels of land within the Prairie Proviences of Western Canada. The east-west baseline for the DLS system was established at the Canada/US border (along 49°N parallel), with Township lines running east-west (6 mile intervals parallel to the baseline) and are numbered from 1, increasing northward. |

|

The north-south baseline (known as the Principal Meridian) is set west of Winnipeg, MB at approximately 97.5°W longitude. Range lines run north-south, at 6 mile intervals parallel to the Principal Meridian. The intersection of Townships and Range lines form a parcel of land (called Townships), measuring 6 miles by 6 miles in size. Due to the curvature of the Earth, Township squares become smaller as you travel northward. To maintain the 6 mile size, coorection lines were used to adjust the Range lines. At the second Township line, and every 4 Township lines from there, the Range lines were adjusted to be 6 miles apart. As a result, Township squares become offset with increasing distance from the Principal Meridian. A second meridian was established at 102°W longitude, with Range lines surveyed parallel to this new meridian. Township squares were once again aligned in a column, with Range numbers starting over again at 1. This measurement is continued westward, with Meridians occuring every 4° of longitude past 102°W. |

|

|

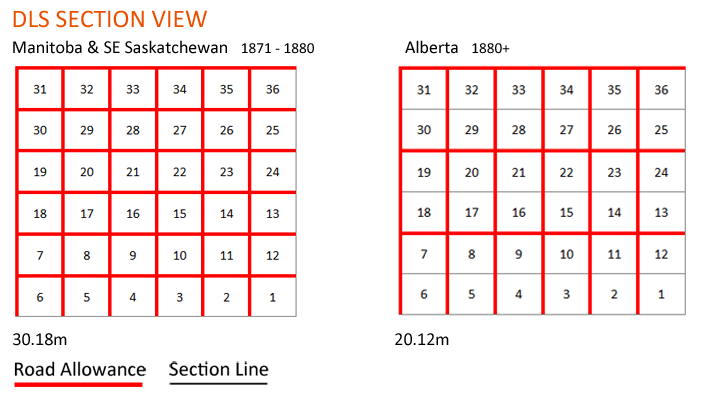

A 6 mile by 6 mile Township square is subdivided into 1 mile by 1 mile parcels known as a section. Sections are numbered from the lower right corner, westward 1 to 6, then up and eastward for 7 to 12. This "snake" pattern ends up in the 36th section located in the upper right corner of the Township. LEGAL SUBDIVISION A section can be subdivided into 1/4 mile by 1/4 mile parcels known as a Legal Subdivision (LSD). These number 1 to 16, starting from the lower right corner, following the same pattern as the Section subdivision. Four LSD's form a quarter section parcel. |

Road Allowances

Road AllowancesThe following guide is used to aid in understanding road allowances within the Dominion Land Survey system.

Road Allowance Width:

Alberta/Saskatchewan |

20.12m |

Manitoba |

30.18m |

Road allowances are designated fixed width areas that run inbetween certain sections of a township. Although many road allowances contain physical roads, not all road allowances have an actual road built on them. Road allowances are one of the differences between the Canadian DLS and the American Public Land Survey System, which leaves no extra space for roads.

The road allowances add to the size of the township (they do not cut down the size of the sections): This is the reason the baselines are not exactly 39km apart.

Differences between Road Allowances

Many different surveys took place in the late 1800's, with two being prominently used today. Surveys that took place between 1871 to 1880 encompass most of southern Manitoba, parts of south eastern Saskatchewan and around the Prince Albert area. The important difference between the two survey methods are the width of the road allowances, and the frequency of road allowances in between each township.

Sections surveyed from 1871-1880 (Manitoba & SE Saskatchewan) contain road allowances that are 30.18m wide (1.5 chains), run north-south and east-west between all townships.

Sections surveyed from 1880 onward contain road allowances that are 20.12m wide (1 chain), but running east-west only fall on the north side of townships 7 to 12, 19 to 24, and 31 to 36. This results in a road allowance every mile progressing east-west and every two miles progressing north-south.

Measured from the edge of the section in Alberta/Saskatchewan.

Measured from the middle of the road allowance in Manitoba.